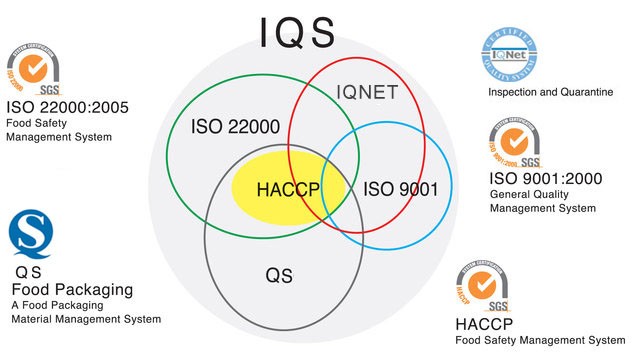

JIECHENG Printing Inc. has gained accreditation for the International quality and quantity control certifications ISO9001、ISO22000、HACCP、QS and IQNET. This demonstrates that JIECHENG Flexible Packaging have attained international standards in our flexible packaging products, processes and procedures. (products, processes and procedures.)

With our own in-house developed Integrated Quality System (IQS), JIECHENG strives to provide the highest standard in quality and safety. By carefully integrating ISO9001, ISO22000, HACCP、QS and IQNET standards, our IQS streamline these standards to create one unifying standard covering all essential areas for both quality and safety issues.

When the plant was built

During the planning stage of the factory, international food packaging standards and requirements were incorporated into the construction plans, laying a solid foundation for our integrated quality system. Upon completion, JIECHENG’s ultra modern production plant has far exceeded the basic standards and requirements for a flexible packaging manufacturer, and can be favorably compared to a pharmaceutical factory of international standard.

Why JIECHENG Flexible Packaging needs IQS

Managing various local and international quality standards is never an easy task. JIECHENG Flexible Packaging has achieved this goal, thanks to its focus on the pursuit of quality and the philosophy within its Integrated Quality System. JIECHENG Flexible Packaging is subjected to more than 30 audits and audit-related meetings every year. The consistent management of these quality standards is a critical factor in maintaining standards and that is why the Integrated Quality System plays a major role both now and for the future.

What IQS is about

The Integrated Quality System is made up of the following elements.

One major Quality Manual oversees not only 19 Quality Procedures but more than 100 Quality Records. Within this hierarchy, each single procedure, regardless of significance, can be well defined and recorded which ensures the quality assurance that our customers and we seek.

Some of the Quality Procedures

- Document Control Procedure

- System Record Control Procedure

- Management Review Procedure

- Internal and External Audit Procedure

- Training Procedure

- Production Environment Control Procedures

Some of the Work Instructions

- Raw material inspection standard

- Product quality standard

- Bar-code scanning system

- Labeling and traceability system

- New product costing analysis

- Lab. Instrument operation instruction

- Machine operation instruction

- Pest Control

- Generator operation instruction

- Adhesive preparation instruction